Carrying its legacy for over 60 years, we have been continuing to manufacturing large special screws (large cutting screws), long shafts, and twin screw extruder spline shafts. Our pursuit of contributing refined products created by the exquisite technology has been bringing satisfaction to the customers. Try using our products, and we guarantee that you will be satisfied with the quality of these. By all means, please contact us to talk through your business needs.

The most critical element for screws is its precision. We are proud of its outstanding accuracy in meeting our customers requirements with our perfect precision. A screw is vital to make a machine move functionally and we believe that a screw’s precision can be the key to the development of domestic and global market. We continue to commit ourselves to being one of the world excellent screw manufacturers and believe that we are able to contribute to the planet by creating comfort although the task assignment given us is rather partial.

We would like to explain hereunder about our technology maintained for over 60 years, based on which we have been manufacturing screws to satisfy global customers needs. Also, below you will find our actual performances as well.

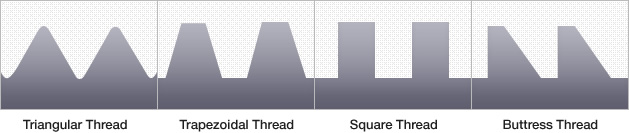

- Triangular Thread (Metric Thread, Inch Thread, Unified Thread)

- Trapezoidal Thread (Metric Trapezoidal Thread {Tr}, 30-degree Trapezoidal Thread, 29-degree Trapezoidal Thread {TW}

- Square Thread

- Buttress Thread

- Multi-Start Thread

- High Lead Screw

- Cross Screw

- Heat Treatment (Induction, Carburizing) Grinding Screw

High accuracy is feasible for all spec screws.

The backlash of external and internal thread can be adjusted with high accuracy.

A thorough check of screw contact is also conducted in the matter of sliding screws under high load.

Based on our performances and know-how accumulated for over the years, a shaft with the maximum length of 20m and maximum weight of 30 tons is possible to be fabricated with a high degree of accuracy.

As for the long shaft fabrication, distortion of materials has been a constant challenge for us. The important point is to not only fix the distortion but to also chose the appropriate materials and the heat treatment. Please also visit our company for the purpose of material sourcing.

Not to mention shaft fabrication, spline gear cutting and its fabrication is possible up to maximum 10 meters with various shapes like involute, square and hexagon.

- Screws and Nuts for Decreased Pressure (Increased Pressure) An apparatus of Various Rolling Mills

- Screws and Nuts for Peripheral Equipments of Various Rolling Mills

- Pull-rod Coupling Clevis for Steel Pipe Manufacturing Equipments

- Bell Rods for Shaft Furnaces

- Shafts for Various Metals Manufacturing Machinery Equipments

- Tie Rods and Nuts for Various Large-Size Presses

- Screws and Nuts for Screw Press

- Tie Bars & Nuts for Large Injection Molding Machineries

- Screw Shafts for Twin-Screw Extruders

- Screws and Nuts for Slider Control Equipment

- Bending Rolls

- Tie Rods & Nut for Aluminum and Copper Extruder

- Piston Rods for Hydraulic Cylinders

- Piston Rods for Hydraulic Cylinders for Floodgate (SUS304N4)

- Screw & Nuts for Horizontal Retractable Jib Crane

- Various Feed Screws & Nuts, Screws

- Gate Spindles & Stem Nuts for Floodgate

- Tension Rods for Bridge Cable

- Screws & Nuts for Stage Elevators

- Camshafts

- Boring Bars for Boring of Aft Peak Tube

- Traverse Shafts for Winches

- Screw Axles and Spline Axles for Paper Working Machineries

- Screws & Nuts, Poles for Material Testing Machineries

- Feed Screws & Nuts for Other Industrial Machineries

- Screws & Worm Wheel for Worm Jack

- Agitating Axles for Agitators

- Shafts for Other Industrial Machineries

| Act on lathe-bed | Act on Saddle | Core Distance |

| 1,320㎜ | 1,000㎜ | 20,000㎜ |

| 1,320㎜ | 900㎜ | 16,000㎜ |

| 950㎜ | 560㎜ | 15,000㎜ |

| 700㎜ | 430㎜ | 15,000㎜ |

| 1,200㎜ | 800㎜ | 10,000㎜ |

| 1,010㎜ | 600㎜ | 10,000㎜ |

| 950㎜ | 560㎜ | 8,000㎜ |

| 1,800㎜ | 1,300㎜ | 5,000㎜ |

| 850㎜ | 450㎜ | 5,000㎜ |

| 1,320㎜ | 900㎜ | 4,000㎜ |

| 650㎜ | 360㎜ | 3,900㎜ |

| 650㎜ | 360㎜ | 2,400㎜ |

| 650㎜ | 360㎜ | 1,500㎜ |

| 950㎜ | 600㎜ | 8,000㎜ |

| 950㎜ | 550㎜ | 6,000㎜ |

| 750㎜ | 550㎜ | 6,000㎜ |

| 300㎜ | 2,800㎜ | |

| 300㎜ | 2,000㎜ | |

| 150㎜ | 2,000㎜ |

| Act on lathe-bed | Act on Saddle | Core Distance |

| 600㎜ | 400㎜ | 5,000㎜ |

| 450㎜ | 250㎜ | 1,000㎜ |

| 900㎜ | 620㎜ | 7,000㎜ |

| 650㎜ | 350㎜ | 5,000㎜ |

| 630㎜ | 400㎜ | 5,000㎜ |

| 500㎜ | 200㎜ | 5,000㎜ |

| 630㎜ | 400㎜ | 3,000㎜ |

| 400㎜ | 150㎜ | 3,000㎜ |

| 500㎜ | 230㎜ | 600㎜ |

| External Diameter of Maximum Lathe Turning | The Height of Maximum Lathe Turning |

| 1,350㎜ | 1,250㎜ |

| Displacement of each axis | Spindle Nose | |

| CNC Universal Lathe Machine |

X-axis:2,000㎜ Y-axis:850㎜ Z-axis:630㎜ |

JISNO.50 |

| Universal Milling Machine | JISNO.40 | |

| Screw Cutting lathe Machine (Spline Processing Machine) |

6 units |

| Inclination on bed | Core Distance | |

| Cylindrical Grinding Machine | 1,000㎜ | 12,000㎜ |

| Screw Grinder | 480㎜ | 3,050㎜ |

| Radial Drilling Machine | |

|---|---|

| Band Sawing Machine | |

| Overhead Travelling Crane | 20t / 5t, 10t /a set, 5t / a set, 2.5t / 2 sets, 2t / 2 sets |

| Gosho Screw Co.,Ltd | |

| Wataru Shirato | |

| 2-1-1 Shinke-cho, Yao-shi, Osaka, 581-0811 | |

| +81-72-997-6731 | |

| +81-72-996-3134 | |

| June, 1959 (Established: October, 1949) |